- Home

- Service nz

Pentair Service in NZ - People you can trust

Our mission is to provide service across multiple industries with a focus on optimizing your processes and partnering with you to achieve sustainability and performance goals.

WITH PENTAIR NZ SERVICE, YOU WILL BE BENEFITTING FROM:

- Improved operation uptime

- Product quality and safety

- Reduced utility consumption

- Reduced maintenance costs

- Expert know-how

- Valve refurbishment from a local based Hygienic valve manufacturer

- Variety of service options to choose from.

We cover services for

- Hygienic & Industrial Valves of all brands

- Pentair Haffmans Quality Control Equipment

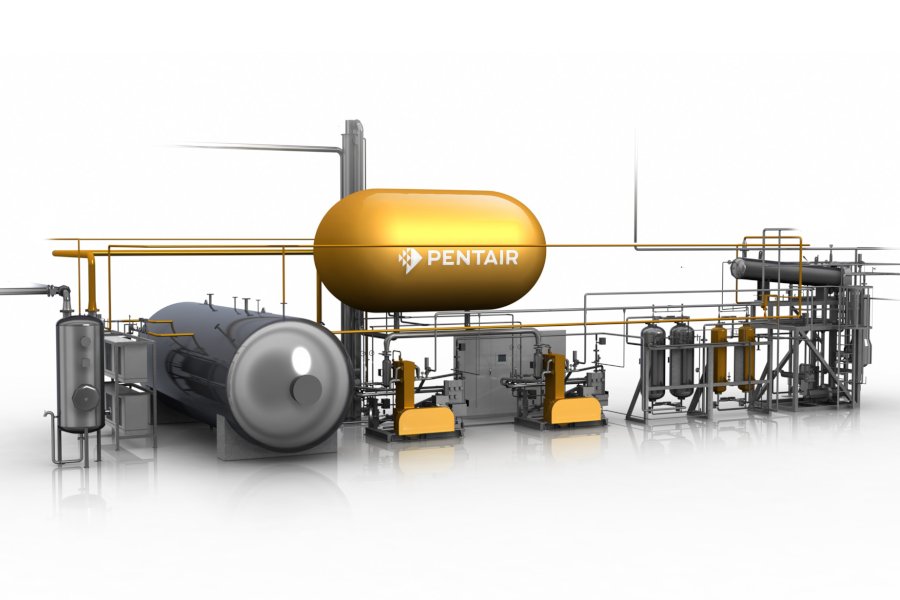

- Pentair Haffmans CO2 Recovery Plants

- Pentair Biogas Upgrading Plants

- Pentair Water Softener & Carbon Filtration System

Contact our Service team

What makes us special: Mobile workshop

Purpose built mobile facility with tools and equipment required to conduct quality service and device testing, allowing the Pentair service team to have an on-site workshop. For larger work scopes this ensures existing site maintenance teams are not disrupted.

Preventive maintenance

Maintenance costs are estimated to be 35 % of production costs and can be significantly reduced by planned service intervals.

During these service intervals, all necessary preventive and corrective maintenance steps are taken to ensure your plant's performance, reduce costs, and optimize productivity.

By doing this, we address urgent maintenance work and repairs and take preventative measures to help minimize maintenance time and unscheduled downtime, helping to contribute towards a lower total cost of ownership (TCO).

Hygienic Valve Refurbishment

Bring new life to existing equipment, allow Pentair to refurbish older valves, removing pitting and other damage to stainless steel components.

Pentair has a Hygienic valve manufacturing facility located in Hamilton, New Zealand, with the capability to clean up older valves helping to extend their life. This process is a cost-effective way to maximize your assets. Depending on the condition of the components, it might be possible to re-polish or re-machine the surface.

CO2 recovery plants maintenance

Your carbon dioxide (CO2) system is an integral part of your production process and keeping it up and running is critical for the continued success of your operation. Pentair is your partner to optimize the life cycle management of your system.

With a wealth of experience in CO2 systems in the brewing, beverage, and selected niche markets, Pentair has gathered extensive know-how in the intricacies of servicing and maintaining CO2 plants. As a result, we have various service options for you to choose from.

Service audits

When it comes to customer satisfaction, Pentair takes the initiative whenever possible.

We continuously strive to realize the ‘best of the best’ standard by meeting, anticipating, and exceeding our customers’ requirements.

We offer unparalleled customer service and technical support.

On-site inspection and preventative maintenance of your Pentair system(s) is an efficient way to maximize your plant performance. All visits include a detailed report on your plant’s current status and performance.

Accreditation - Certified IANZ laboratory for:

- Pressure and vacuum type measurements on switches, sensors, transducers & gauges

- Temperature loop, sensors, indicators, recorders and transmitter measurements

- Process instruments validation (pressure, temperature)

- Differential pressure measurements (flow)

- Autoclave temperature validation

- Laboratory spatial analysis

Pentair Hamilton, New Zealand site