O2 MANAGEMENT OF YOUR BEVERAGE

Distinct taste and superior quality – that’s what consumers aim for when buying your product. The constant need for efficiency, variety and flexibility in production puts additional pressure on food and beverage processors.

Pentair's O2 Management Solutions puts you at ease when it comes to product quality and optimizing the management of O2 as your key quality parameters - so you can focus on that distinct taste.

Haffmans Quality Control Equipment is available for portable, lab or inline usage, and include the measurement of O2. So start now by measuring your O2 levels during and after production and improve your taste stability and shelf life.

BENEFITS

- Longer shelf-life

- Reliable measurement gives you peace of mind

- Taste stability due to better control

- Manage the customer experience of your beverage

-

IMPORTANCE OF MEASURING O2

-

O2 management is important because it's influencing taste and shelf life.

Taste

Proper O2 management gives a stabile taste experience because of the negative influence of oxygen on the microbiological changes of the beverage, especially when it comes to beer.Shelf life

Also, shelf live will be shorter with more oxygen in your beverage. It is especially important to have a stable shelf life because your beverage should have the same taste experience by the end of the best before date as when it was freshly bottled.Multiple parameters can be measured with regards to Oxygen:

- DO = dissolved oxygen in the liquid

- HSO = head space Oxygen, present in the gas in the headspace

- TPO = Total Package Oxygen and is the sum of HSO+DO.

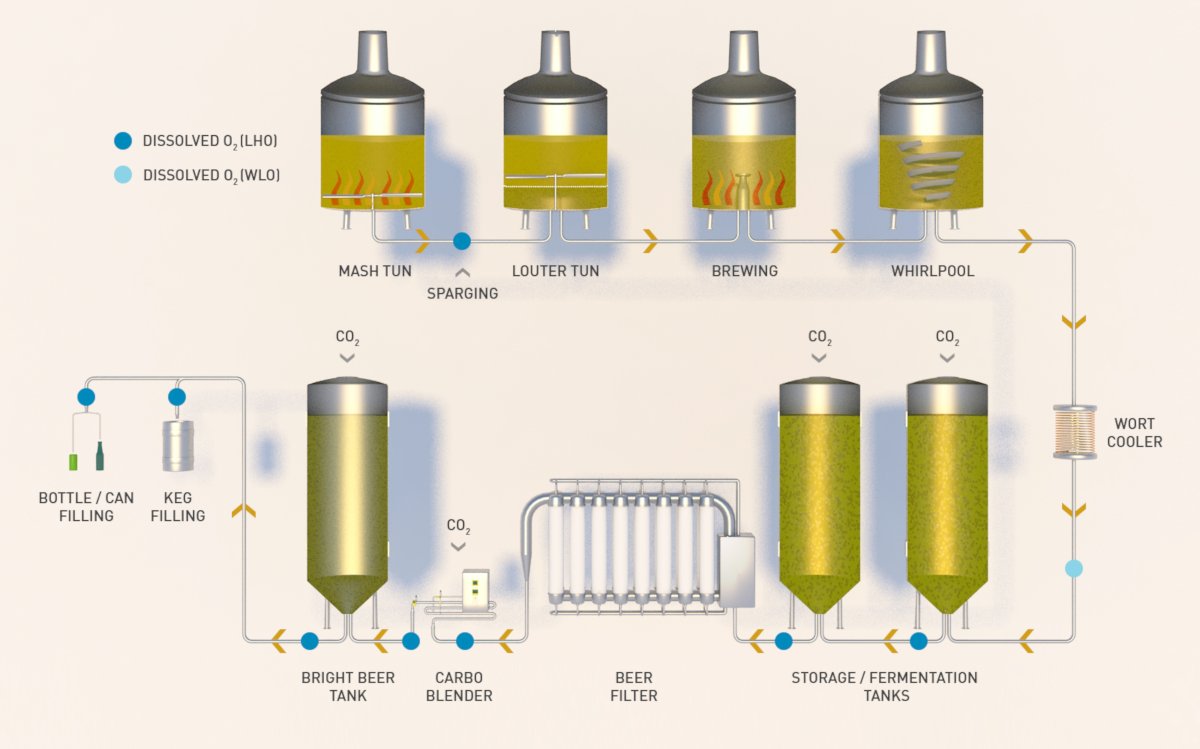

WHERE TO MEASURE O2 IN YOUR PROCESS

Pentair Haffmans' Quality Control Instruments help to understand and manage your O2 levels throughout your production process. The most essential steps are summarized below.Brewhouse

Monitoring the aeration of the wort prior to fermentationCold Block

- Checking oxygen pickup during fermentation

- Monitoring the oxygen pickup during filtration

Packaging

Monitoring oxygen pickup during the packaging process Final in-process quality controlLaboratory

Final product quality control checkO2 content of carbonated beverages

- in tanks

- in pipelines

- in kegs (pre-mix)

- on dispensing systems

- in bottles and cans (in combination with ISD-SP)

-

MEASURE O2 IN BREWING PROCESS

-

-

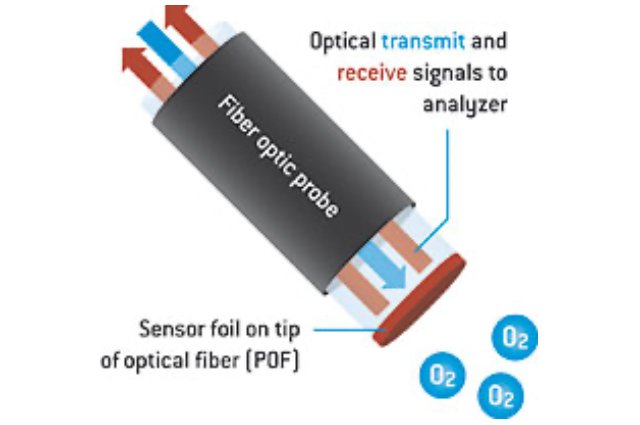

OPTICAL O2 MEASUREMENT TECHNOLOGY

-

- Oxygen (O2) sensor spot is in contact with the medium

- The sensor spot is intensely illuminated by a light source for a short time.

- Depending of the O2 content in the medium, the sensor spot will give a light signal.

- A photo detector measures this light signal, and from it the oxygen content is calculated.

- The electronics modulates the emitted light intensity and measures a phase shift to the received light.

Pentair's Solutions for the Brewing Industry

Pentair Industrial Solutions is renowned worldwide for its innovative and sustainable products and systems that enhance industrial applications by streamlining operational efficiency, maintaining quality, and reducing water-, energy- and solid waste footprints, as well as carbon emissions.

pentair gehaltebus

The Pentair Gehaltebus is a demonstration tour bus traveling across Mainland Europe, the United Kingdom, and North America, bringing Pentair Haffmans Quality Control Equipment to the doorsteps of breweries, distilleries, wineries, and beverage producers.

RELATED PRODUCTS

HAFFMANS DO CONTENT MEASUREMENT DEVICE - OXY-2GO

For smaller breweries needing a cost-effective yet reliable DO content measurement device, Pentair Haffmans Oxy-2Go is the answer.

HAFFMANS PORTABLE OPTICAL CO2/O2/TPO METER C-DGM

Combining the internationally accepted determination of the dissolved CO2 content with a highly accurate dissolved O2 and TPO measurement.

PACKAGE ANALYZER - HAFFMANS C-TPO SELECTIVE

Differentiated O2 and selective CO2 measurement for breweries that use N2 assisted filling instead of CO2, or inject N2 into the product during packaging.

HAFFMANS AUTOMATIC INPACK TPO METER - TPO

Differentiated measurement of headspace O2 and DO provides immediate insight in the performance of your filling operation.

HAFFMANS INPACK AIR METER - IAM

Determining the air content in the headspace volume as well as the total air content in the beverage based on CO2 absorption by caustic.

HAFFMANS GAUGE CALIBRATION DEVICE - GCD

A dedicated precision instrument for calibrating pressure gauges and digital pressure sensors. Universally applicable, it can be used for all kinds of pressure calibrations and is compliant with international standards.

HAFFMANS PORTABLE OPTICAL O2 / TPO METER O-DGM

Portable optical O2 / TPO meter combining high accuracy with excellent measurement stability, frequent calibration is not required.

HAFFMANS AUTOMATIC PACKAGE CONTENT ANALYSIS SYSTEM - AUTOMATOR

Automatically measuring all relevant quality parameters directly in the filled package in a single measurement cycle.

PENTAIR HAFFMANS AUTOMATIC INPACK TPO/CO2 METER C-TPO

The differentiated measurement of headspace O2 and DO provides immediate insight in the performance of the filling operation. Fully automated, multiple determinations of TPO and CO2.

HAFFMANS OPTICAL IN-LINE CO2 / O2 METER - AUCOMET-I

Fast and accurate in-line determination of the CO2 / O2 content in beer and beverages based on the internationally standardized method of Henry’s Law.

HAFFMANS IN-LINE OPTICAL O2 METER - OGM

Combination of high accuracy with excellent measurement stability. Greatly improved response times compared to traditional O2 measuring devices.

HAFFMANS TOTAL LAB SOLUTIONS - TLS

Customized laboratories for quality analysis throughout the production process. From concept to after sales service.

RELATED CASE STUDY