Product Information

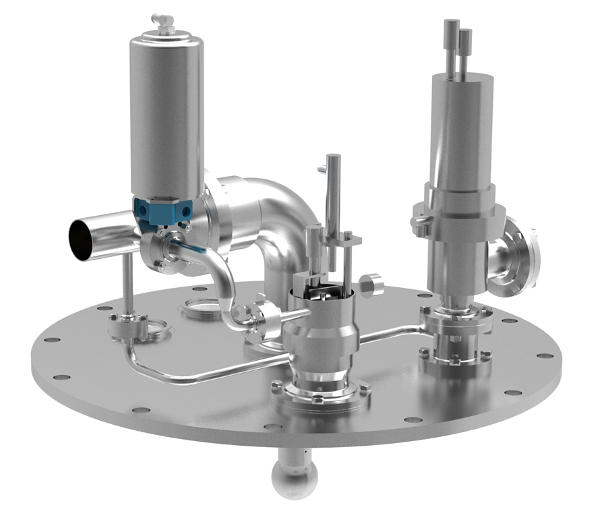

Pentair Südmo’s TankTop assembly offers a proven simple and reliable compact tank top system that allows the addition and removal of gases and CIP cleaning fluid using one process connection.

Benefits

- Compact system

- Flexible with customizable executions

- Cost effective proven technology

- No automation required

- No additional cleaning piping

- Cleanable and self-draining

- Easy to install and maintain

- Meets all safety requirements

-

FUNCTIONAL DESCRIPTION

-

Operating a tank in the food, beverage, pharmaceutical, and cosmetics industries requires adherence to process, safety and hygiene standards. One of the process related challenges comes when adding or removing carbon dioxide, fermentation gases or nitrogen blanketing while ensuring optimal cleaning. The tank must also be protected from damage caused by overpressure or vacuum.

Tanktop assemblies, up to a certain diameter, can have the safety valve directly connected to the unit to protect against overpressure and the vacuum valve directly connected to protect against vacuum. This option, in many applications, eliminates the expense of a tank dome plate. In addition, optimal cleaning of the complete system and the additional safety fittings is assured.

-

FIELDS OF APPLICATION

-

Pentair's Südmo tank top systems are used across the applications in brewing, food, beverage, winery, pharmaceutical and cosmetic industries.

Downloads

| Title | Download PDF | |

| Brochure | Tank Top System - Südmo TankTop | Download |

| Catalog |

Südmo Components | Contact Us |

RELATED PRODUCTS

Reliable protection against underpressure and over pressure of your storage tanks and other pressure vessels.

SÜDMO LEAKAGE BUTTERFLY VALVES L 587/L 667/L 687

Safe separation of incompatible fluids in a compact design and brings significant advantages over traditional block and bleed installations.

SÜDMO HYGIENIC BUTTERFLY VALVES K 580 / K 660 / K 680

Ideal solution for shut-off function across all segments of the hygienic process industry.

SÜDMO SINGLE SEAT VALVES SVP SELECT

The best basis for efficient and safe production processes due to the wide variety of options provided by our modular system, ease of maintenance, cleanability, and the options for the valves to meet the latest hygiene and aseptic requirements.